INTRODUCTION

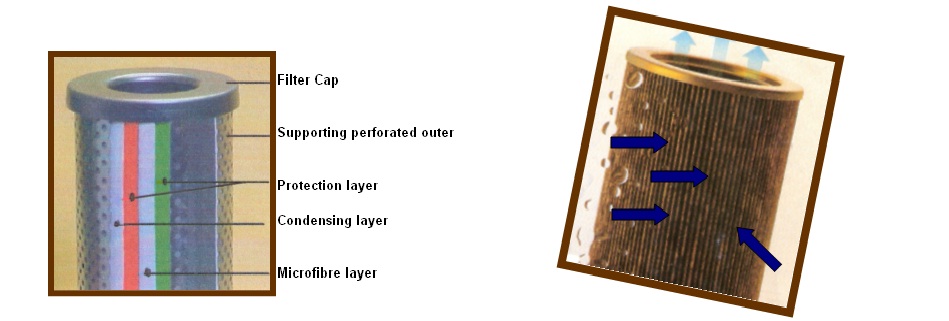

Our many years of experience and development on the extremely demanding requirements in water separation and solids removal from oil and diesel fuels at various flow rates we designed a high efficient coalescer which is a process of continuously uniting tiny water globules suspended in the two large droplets which will now sink at a rapid rate. Large quantities of water or large droplets are generally not a problem in well designed systems, because they rapidly settle in the water boots. The tiny droplet, generated by pumps, transformers and condensation, is a real threat to oil systems, because of the fact that they will stay in suspension. Simple separators can not effectively cater for this problem. High efficiency coalescers comprise a multi layer of media as shown below (in picture 1) in the form of replaceable cartridge.

SEPARATOR HOUSINGS

This allows fuel to pass freely but provides a coalescing and water separation action which deposits the water at the bottom of the housing.

STANDARD HOUSING DESIGN

Filter separators are economical, compact housings for superior inline filtration protection and efficient removal of water and solids from oil and fuel. The single cartridge housings are easy to maintain.

Design

► Body: Carbon steel or stainless steel

► Design pressure: as per pressure specification

► Inlet and outlet connections: 20mm NPT female treaded up to 400mm Flanged connection

Optional

► Pressure gauge kit

► Automatic water drain